GM directs major investment in local workforce to launch three new vehicles

2026-01-29

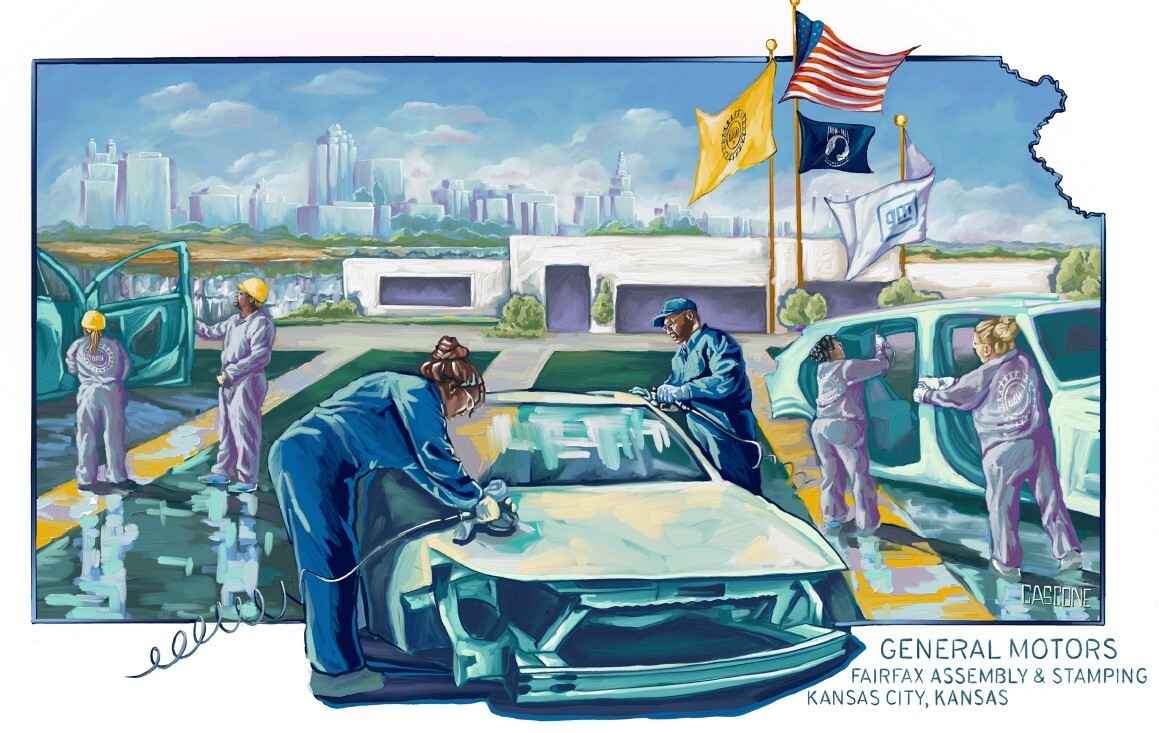

General Motors’ Fairfax Assembly Plant in Kansas City, Kansas, has been a mainstay in the area since 1946 and is now at the forefront of the company’s latest manufacturing innovations. The plant is currently producing the Chevrolet Bolt, an electric vehicle, soon to be followed by the gas-powered Chevrolet Equinox and a next-generation Buick compact SUV.

On top of nearly $5.5 billion in recent manufacturing investments, GM is putting another $30 million into preparing our Fairfax workforce for these major vehicle launches – to ensure our people stay at the cutting edge of advanced manufacturing and continue driving American excellence.

This investment supports:

Upskilling team members for more advanced roles as technology evolves

Cross‑training that builds flexibility between EV and ICE production

Safety, quality and launch‑readiness training to ensure every vehicle is one customers love

A generational plant, a next‑generation workforce

Fairfax has been a cornerstone of GM manufacturing, with many workers and their families — including Fairfax Plant Director Michael Youngs – building careers across generations. Youngs, a third generation GM employee, started his GM journey at Fairfax over 30 years ago and now leads the plant’s trio of major launches.

“For us, this work is more than building vehicles – it’s building a legacy. General Motors has been a place where families grow their careers across generations, including my own,” Youngs said. “The investment in people isn’t just about preparing for the production of new vehicles; it’s about giving our people the opportunity to build a future their families can be proud of.”

Part of a company‑wide workforce strategy

These workforce investments are one part of GM’s enterprise strategy to support current and future employees at every stage – from K‑12 STEM/STEAM education and apprenticeship programs to tuition assistance and advanced technical on-the-job training.

Company‑wide, GM has:

Invested $500 million in U.S. manufacturing apprenticeships and upskilling programs in the past five years.

Trains roughly 2,500 employees per year in advanced manufacturing, electrification and emerging technologies at its Technical Learning University in Warren, MI.

Provided up to $8,000 per year in tuition assistance, investing $66 million in higher education over the past five years to help thousands of employees pursue certificates and degrees that support long‑term careers.

As Fairfax transitions from the Chevrolet Bolt to Equinox and then adds the Buick SUV to its lineup, these investments ensure employees are prepared from the start.

Investing in people to secure Fairfax’s future

The decision to bring more product to Fairfax is centered on one idea: long‑term competitiveness starts with people.

GM’s more than $30 million in Fairfax‑specific training:

Supports the skills and careers of the people who build our vehicles

Strengthens a key U.S. manufacturing site

Shows how investing in people – not just tooling – drives quality, flexibility and American competitiveness

The effects of this investment are greatly amplified when you factor in all the training conducted across GM’s manufacturing sites to gear up for new product launches.

Fairfax demonstrates what happens when deep experience meets new investment: a plant ready for whatever comes next, and a workforce prepared to power GM’s future.

General Motors’ Fairfax Assembly Plant in Kansas City, Kansas, has been a mainstay in the area since 1946 and is now at the forefront of the company’s latest manufacturing innovations. The plant is currently producing the Chevrolet Bolt, an electric vehicle, soon to be followed by the gas-powered Chevrolet Equinox and a next-generation Buick compact SUV.

On top of nearly $5.5 billion in recent manufacturing investments, GM is putting another $30 million into preparing our Fairfax workforce for these major vehicle launches – to ensure our people stay at the cutting edge of advanced manufacturing and continue driving American excellence.

This investment supports:

- Upskilling team members for more advanced roles as technology evolves

- Cross‑training that builds flexibility between EV and ICE production

- Safety, quality and launch‑readiness training to ensure every vehicle is one customers love

A generational plant, a next‑generation workforce

Fairfax has been a cornerstone of GM manufacturing, with many workers and their families — including Fairfax Plant Director Michael Youngs – building careers across generations. Youngs, a third generation GM employee, started his GM journey at Fairfax over 30 years ago and now leads the plant’s trio of major launches.

“For us, this work is more than building vehicles – it’s building a legacy. General Motors has been a place where families grow their careers across generations, including my own,” Youngs said. “The investment in people isn’t just about preparing for the production of new vehicles; it’s about giving our people the opportunity to build a future their families can be proud of.”

Part of a company‑wide workforce strategy

These workforce investments are one part of GM’s enterprise strategy to support current and future employees at every stage – from K‑12 STEM/STEAM education and apprenticeship programs to tuition assistance and advanced technical on-the-job training.

Company‑wide, GM has:

- Invested $500 million in U.S. manufacturing apprenticeships and upskilling programs in the past five years.

- Trains roughly 2,500 employees per year in advanced manufacturing, electrification and emerging technologies at its Technical Learning University in Warren, MI.

- Provided up to $8,000 per year in tuition assistance, investing $66 million in higher education over the past five years to help thousands of employees pursue certificates and degrees that support long‑term careers.

As Fairfax transitions from the Chevrolet Bolt to Equinox and then adds the Buick SUV to its lineup, these investments ensure employees are prepared from the start.

Investing in people to secure Fairfax’s future

The decision to bring more product to Fairfax is centered on one idea: long‑term competitiveness starts with people.

GM’s more than $30 million in Fairfax‑specific training:

- Supports the skills and careers of the people who build our vehicles

- Strengthens a key U.S. manufacturing site

- Shows how investing in people – not just tooling – drives quality, flexibility and American competitiveness

The effects of this investment are greatly amplified when you factor in all the training conducted across GM’s manufacturing sites to gear up for new product launches.

Fairfax demonstrates what happens when deep experience meets new investment: a plant ready for whatever comes next, and a workforce prepared to power GM’s future.