By Chris Perkins, writer and editor, GM News

Electric vehicles are General Motors’ “North Star.” Experience the smooth, quiet, near-instant power of an EV for yourself, and you’ll understand why.

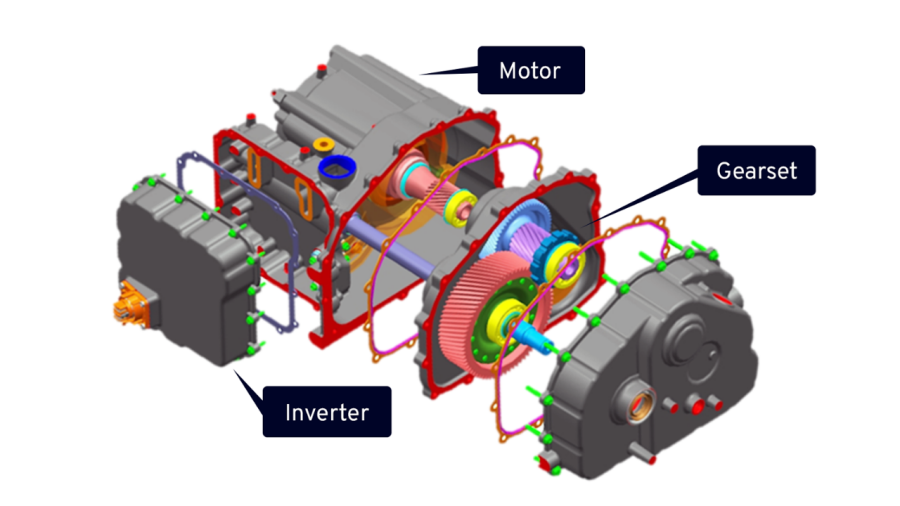

Every GM EV uses drive units – which consist of motor, inverter, and gearset – to turn electricity from the battery into motion. GM has more than a century of experience advancing propulsion system technology. That expertise allows GM to design most drive units in-house.

One way to easily understand an EV drive unit is to compare it to an orchestra. There are three major components that make up our “band.” Let’s dive in to see how each plays its part.

Inverter

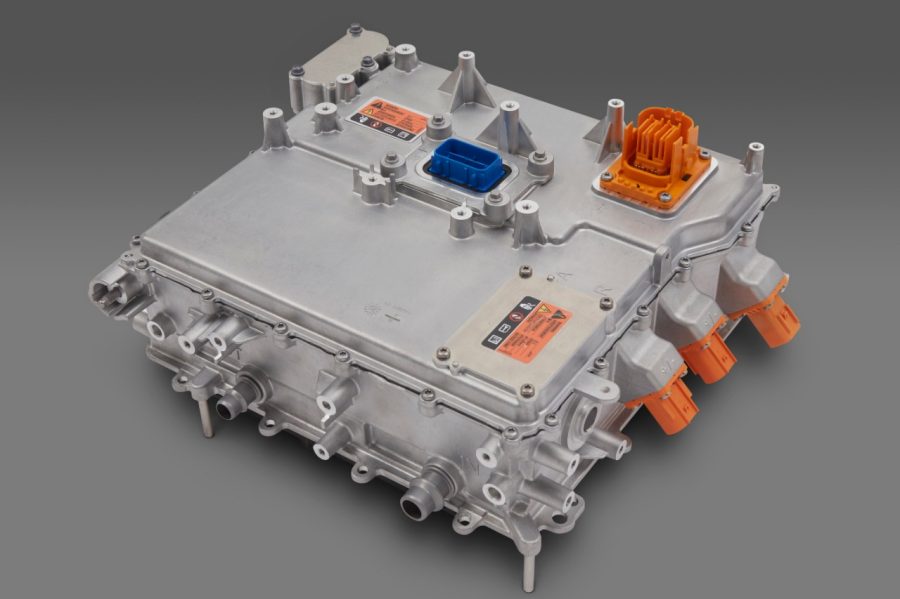

Every orchestra needs a conductor, and that’s where the inverter comes in.

In an EV, the battery stores energy as direct current (DC), but the motor needs alternating current (AC) to generate rotation. DC electricity flows in one direction, whereas AC current switches directions The inverter is responsible for this energy conversion – taking DC power stored in the battery and turning it into AC to power the motor.

An inverter uses switches that open and close in different combinations thousands of times per second to do this. This switching sends current to the stator in highly controlled pulses, creating the rotating magnetic field that spins the rotor. Basically, the inverter is converting and directing energy to get the motor moving, much like how a conductor directs the musicians to play in perfect rhythm.

Motor

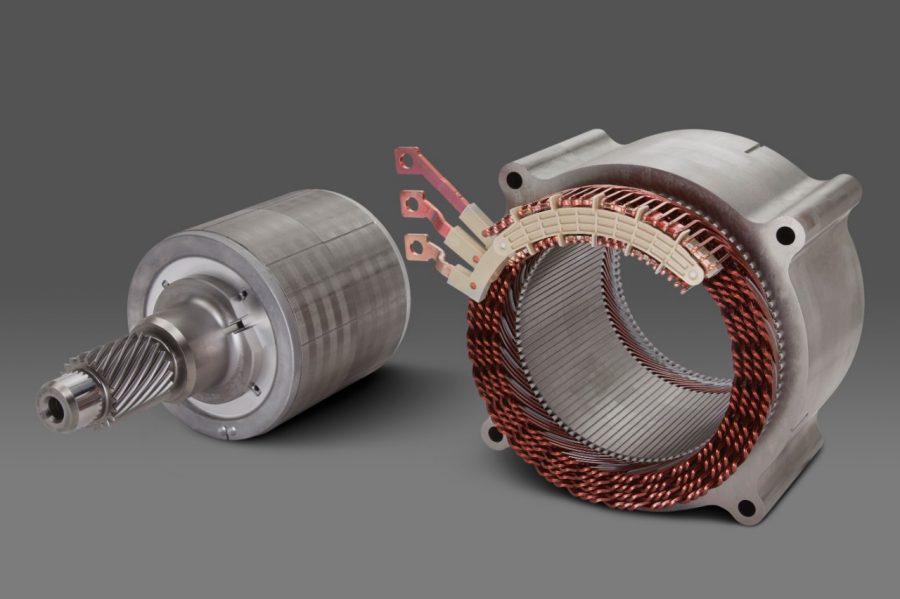

CAPTION: (L to R): Rotor and stator.

If the inverter is like a conductor, that means the motor represents the musicians – it’s what actually creates the motion that you feel.

An electric motor is a surprisingly simple device. There’s only one moving part, called the rotor. When the rotor spins, it drives the wheels that push your EV down the road.

Most GM drive units use permanent magnet propulsion, meaning the motor’s “instruments” are magnets. Understanding how it works really goes back to playing with magnets as a kid. Each magnet has a north and south pole. Opposite poles attract, and similar poles repel each other. Electric motors use these magnetic forces to turn electrical energy into rotational force, called torque.

At the heart of an electric motor, you have the rotor, which is filled with magnets and rotates on a shaft. Encircling the rotor is a second stationary component called the stator, which features copper wiring wound around a core. When electricity is applied to the stator, it creates a magnetic field that spins around the rotor; the magnets in the rotor then follow this magnetic field around, spinning the rotor and creating torque.

Gearset

All of this music needs to go somewhere – and that’s where the gearset comes in. The gearset is like the acoustic environment or the sound system, delivering the music to the audience (in this case, the wheels).

Electric motors work efficiently across a much broader speed range (measured in revolutions per minute, or RPM) than the typical internal-combustion engine. Thus, most EVs only need a single-speed gearset. The rotor shaft drives an arrangement of gears that connect to the axles to transmit torque to the wheels, much like a state-of-the-art sound system or concert venue beautifully transmits music to the audience.

Another benefit: An electric motor is perfectly happy spinning backwards or forwards. In an EV, you don’t need a separate set of gears to make the car back up – when you shift into Reverse, the EV’s computer simply tells the drive unit to spin in the opposite direction.

CAPTION: A complete electric drive unit.

Deceptively Simple

On the surface, EV propulsion systems are wonderfully simple, with relatively few components required to turn raw energy into motion. On an electronic level, of course, the way the process works is very complex, controlled by highly advanced software driven by decades of innovation. All of this combines to deliver harmonious performance that GM is proud to feature in the broadest EV portfolio in America. That’s how the near-silent EV driving experience can be music to your ears.

Electric vehicles are General Motors’ “North Star.” Experience the smooth, quiet, near-instant power of an EV for yourself, and you’ll understand why.

Every GM EV uses drive units – which consist of motor, inverter, and gearset – to turn electricity from the battery into motion. GM has more than a century of experience advancing propulsion system technology. That expertise allows GM to design most drive units in-house.

One way to easily understand an EV drive unit is to compare it to an orchestra. There are three major components that make up our “band.” Let’s dive in to see how each plays its part.

Inverter

Every orchestra needs a conductor, and that’s where the inverter comes in.

In an EV, the battery stores energy as direct current (DC), but the motor needs alternating current (AC) to generate rotation. DC electricity flows in one direction, whereas AC current switches directions. The inverter is responsible for this energy conversion – taking DC power stored in the battery and turning it into AC to power the motor.

An inverter uses switches that open and close in different combinations thousands of times per second to do this. This switching sends current to the stator in highly controlled pulses, creating the rotating magnetic field that spins the rotor. Basically, the inverter is converting and directing energy to get the motor moving, much like how a conductor directs the musicians to play in perfect rhythm.

Motor

If the inverter is like a conductor, that means the motor represents the musicians – it’s what actually creates the motion that you feel.

An electric motor is a surprisingly simple device. There’s only one moving part, called the rotor. When the rotor spins, it drives the wheels that push your EV down the road.

Most GM drive units use permanent magnet propulsion, meaning the motor’s “instruments” are magnets. Understanding how it works really goes back to playing with magnets as a kid. Each magnet has a north and south pole. Opposite poles attract, and similar poles repel each other. Electric motors use these magnetic forces to turn electrical energy into rotational force, called torque.

At the heart of an electric motor, you have the rotor, which is filled with magnets and rotates on a shaft. Encircling the rotor is a second stationary component called the stator, which features copper wiring wound around a core. When electricity is applied to the stator, it creates a magnetic field that spins around the rotor; the magnets in the rotor then follow this magnetic field around, spinning the rotor and creating torque.

Gearset

All of this music needs to go somewhere – and that’s where the gearset comes in. The gearset is like the acoustic environment or the sound system, delivering the music to the audience (in this case, the wheels).

Electric motors work efficiently across a much broader speed range (measured in revolutions per minute, or RPM) than the typical internal-combustion engine. Thus, most EVs only need a single-speed gearset. The rotor shaft drives an arrangement of gears that connect to the axles to transmit torque to the wheels, much like a state-of-the-art sound system or concert venue beautifully transmits music to the audience.

Another benefit: An electric motor is perfectly happy spinning backwards or forwards. In an EV, you don’t need a separate set of gears to make the car back up – when you shift into Reverse, the EV’s computer simply tells the drive unit to spin in the opposite direction.

Deceptively Simple

On the surface, EV propulsion systems are wonderfully simple, with relatively few components required to turn raw energy into motion. On an electronic level, of course, the way the process works is very complex, controlled by highly advanced software driven by decades of innovation. All of this combines to deliver harmonious performance that GM is proud to feature in the broadest EV portfolio in America. That’s how the near-silent EV driving experience can be music to your ears.