What a battery geek learned in his first year at GM

2025-02-04

By Kurt Kelty, VP, battery, propulsion, and sustainability, General Motors

One year ago, I took a trip that changed everything for me.

After more than 30 years working in battery technology – I started the same year the lithium-ion battery was first commercialized – I found myself in the General Motors design studios in Warren, Michigan. What I saw there set me on a new path, both personally and professionally. I'm now celebrating my first anniversary leading GM’s incredibly talented battery and propulsion teams – and I recently added sustainability to my job portfolio. As someone who measures the carbon footprint of the blueberries I buy, I'm looking forward to diving deeper into our emissions reduction strategy.

That first visit to the Design Center was a "kid in a candy shop" experience, providing me a chance to see design concepts for a wide range of new GM electric vehicles. I came away convinced that this iconic American company was serious about its vision of an all-electric future. Joining GM offered me a once-in-a-lifetime opportunity to bring the auto industry's broadest portfolio of EVs to scale through battery innovation. It also connected directly with my personal life mission: to promote environmental sustainability and reducing emissions.

We are making progress. In 2024, more than 1.3 million Americans bought new EVs, unlocking technological benefits like instantaneous torque, smoother and quieter drives, and convenient home charging. GM was among the fastest growing EV manufacturers, thanks to a big bet made years ago: a scalable battery and electrification platform that now underpins almost a dozen different GM products across our brands, from the affordable Chevrolet Equinox EV with a starting MSRP of $33,600, to the workhorse GMC Sierra EV Denali with a GM-estimated range of up to 460 miles1, to the luxurious Cadillac Escalade IQ. In GM, I’ve found a company that prioritizes customer choice, even when it’s not the easiest engineering solution.

Caption: The Wallace Battery Innovation Center, in Warren, Michigan.

Scaling our core battery technology has been integral to delivering an EV strategy that enables a vehicle portfolio with widely varying designs, sizes, and shapes. Now, we’re accelerating battery innovation to deliver what matters most: more range, faster charging, and lower costs, all while keeping safety at the heart of everything we do.

In 2025, we’ll build on the progress we’ve made, further developing our battery technology to make EVs the best choice for more and more drivers. As I celebrate my one-year anniversary at GM, now is the perfect time to reflect on what we accomplished in 2024 and provide a peek at what lies ahead.

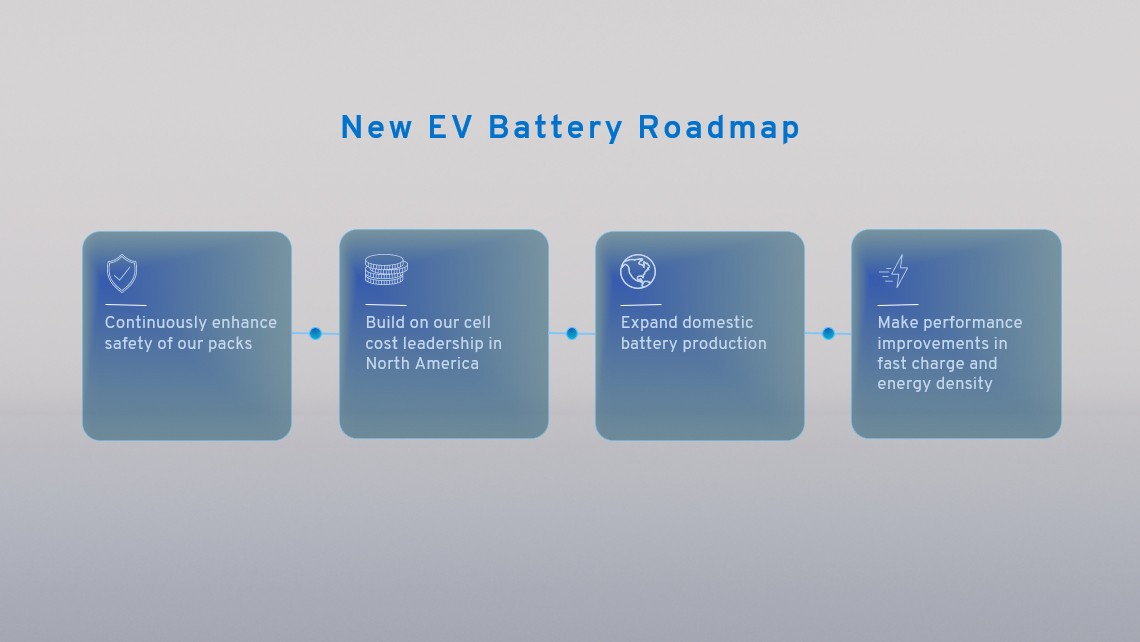

Caption: GM's new battery roadmap, as first revealed at the company's 2024 Investor Day.

A breakthrough year

In 2024, our success in electric vehicles was driven by execution: we scaled battery and EV production, reduced our battery costs, and further enhanced EV performance.

Major milestones from 2024 included:

● Investing in innovation: Our investments in the Wallace Battery Cell Innovation Center in Warren, and the recently announced Battery Cell Development Center on the same campus, are intended to accelerate development and commercialization of new, more affordable EV batteries.

● Advancing battery production: Our Ultium Cells joint venture with LG Energy Solution is one of the largest producers of EV battery cells in North America. In December, we achieved a major milestone with the 100 millionth battery cell produced at the Ultium Cells plant in Warren, Ohio. Achieving this scale with great quality and yield has driven down battery costs significantly in our vertically integrated model and will continue to do so as economies of scale increase.

● Strengthening our strategic partnerships: Progress toward an all-electric future will move faster if we work together. We’ve expanded our technology partnership with LG Energy Solution to jointly develop prismatic battery cells. Additionally, we forged a new battery joint venture with Samsung SDI to produce cells in the U.S.

A look ahead

For GM, 2025 will be a year of intense focus on the details today to optimize the battery technology of tomorrow. We’re developing new form factors for tailored battery systems to serve different vehicles, integrating additional and lower-cost cell chemistries that can deliver range and affordability to customers, and partnering with world-class battery cell makers to onboard these new technologies. Here’s how we’re moving the ball forward this year:

● Advancing technology: Battery innovation isn't about one breakthrough - it's about advancing performance across the entire value chain. That’s why continued R&D on next-generation cell chemistries and form factors, along with steady progress at our battery development and production facilities, will be a major focus. These advancements are aimed at reducing costs, improving energy density, increasing charging speed, and driving sustainability.

● Reducing battery costs: Significant reductions in EV battery costs are within reach, driven by innovations in production processes and material science. In fact, we expect to reduce our combined battery cell and pack costs by $30 per kilowatt hour in 2025. As an industry, battery prices declined in 2024 globally and are expected to continue to come down as many manufacturing investments launch in volume across North America. At GM, we are at the forefront of these advancements, helping to ensure that EVs become more attainable for a broader audience while maintaining high standards of performance and reliability.

● Strengthening North American leadership: GM’s strategic investments and partnerships are expected to bolster the domestic supply chain, create jobs, and enhance North America’s competitiveness in the global EV market. We will continue development of our next-generation battery platform, while moving with urgency to progress key construction activities and ensuring our battery materials supply base does the same. GM is leading the way in American EV infrastructure investments and we continue to secure agreements to localize our supply chain down to the raw materials

Stick with us on this journey! I hope to look back at 2025 as a year that GM drove more innovation and cost-savings in our batteries - boosting EV adoption and making electric vehicles a more compelling option for drivers everywhere.

1: Requires available Max Range battery. On full charge based on development testing and/or analytical projection consistent with SAE J1634 revision 2017 - MCT. Range subject to change prior to production. Actual range may vary based on several factors, including ambient temperature, terrain, battery age and condition, loading, and how you use and maintain your vehicle.

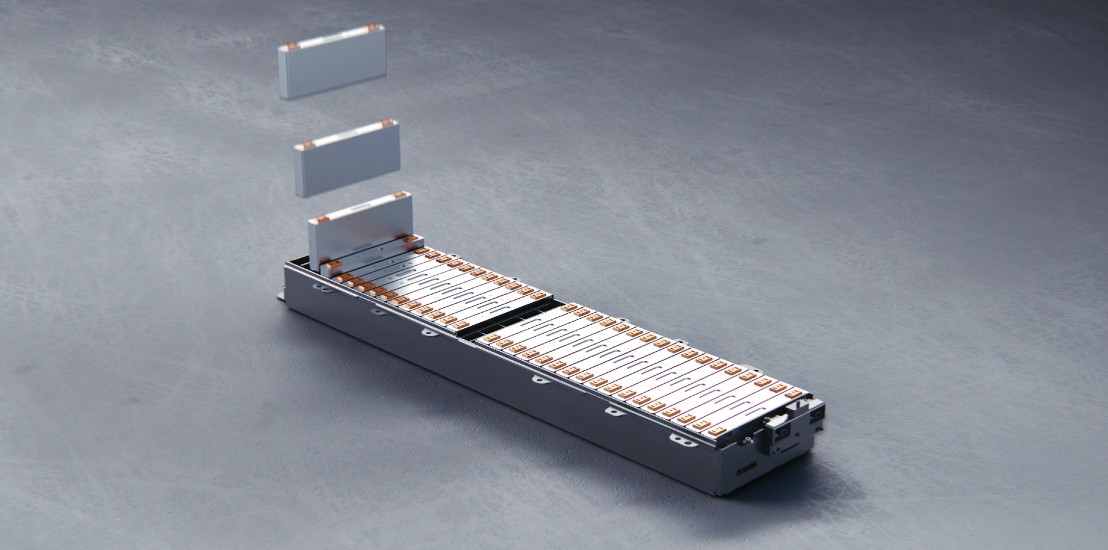

Model of GM's next generation battery module, which will use both prismatic and pouch cells.

By Kurt Kelty, VP, battery, propulsion, and sustainability, General Motors

One year ago, I took a trip that changed everything for me.

After more than 30 years working in battery technology – I started the same year the lithium-ion battery was first commercialized – I found myself in the General Motors design studios in Warren, Michigan. What I saw there set me on a new path, both personally and professionally. I'm now celebrating my first anniversary leading GM’s incredibly talented battery and propulsion teams – and I recently added sustainability to my job portfolio. As someone who measures the carbon footprint of the blueberries I buy, I'm looking forward to diving deeper into our emissions reduction strategy.

That first visit to the Design Center was a "kid in a candy shop" experience, providing me a chance to see design concepts for a wide range of new GM electric vehicles. I came away convinced that this iconic American company was serious about its vision of an all-electric future. Joining GM offered me a once-in-a-lifetime opportunity to bring the auto industry's broadest portfolio of EVs to scale through battery innovation. It also connected directly with my personal life mission: to promote environmental sustainability and reducing emissions.

We are making progress. In 2024, more than 1.3 million Americans bought new EVs, unlocking technological benefits like instantaneous torque, smoother and quieter drives, and convenient home charging. GM was among the fastest growing EV manufacturers, thanks to a big bet made years ago: a scalable battery and electrification platform that now underpins almost a dozen different GM products across our brands, from the affordable Chevrolet Equinox EV with a starting MSRP of $33,600, to the workhorse GMC Sierra EV Denali with a GM-estimated range of up to 460 miles1, to the luxurious Cadillac Escalade IQ. In GM, I’ve found a company that prioritizes customer choice, even when it’s not the easiest engineering solution.

The Wallace Battery Innovation Center, in Warren, Michigan.

Scaling our core battery technology has been integral to delivering an EV strategy that enables a vehicle portfolio with widely varying designs, sizes, and shapes. Now, we’re accelerating battery innovation to deliver what matters most: more range, faster charging, and lower costs, all while keeping safety at the heart of everything we do.

In 2025, we’ll build on the progress we’ve made, further developing our battery technology to make EVs the best choice for more and more drivers. As I celebrate my one-year anniversary at GM, now is the perfect time to reflect on what we accomplished in 2024 and provide a peek at what lies ahead.

GM's new battery roadmap, as first revealed at the company's 2024 Investor Day.

A breakthrough year

In 2024, our success in electric vehicles was driven by execution: we scaled battery and EV production, reduced our battery costs, and further enhanced EV performance.

Major milestones from 2024 included:

- Investing in innovation: Our investments in the Wallace Battery Cell Innovation Center in Warren, and the recently announced Battery Cell Development Center on the same campus, are intended to accelerate development and commercialization of new, more affordable EV batteries.

- Advancing battery production: Our Ultium Cells joint venture with LG Energy Solution is one of the largest producers of EV battery cells in North America. In December, we achieved a major milestone with the 100 millionth battery cell produced at the Ultium Cells plant in Warren, Ohio. Achieving this scale with great quality and yield has driven down battery costs significantly in our vertically integrated model and will continue to do so as economies of scale increase.

- Strengthening our strategic partnerships: Progress toward an all-electric future will move faster if we work together. We’ve expanded our technology partnership with LG Energy Solution to jointly develop prismatic battery cells. Additionally, we forged a new battery joint venture with Samsung SDI to produce cells in the U.S.

A look ahead

For GM, 2025 will be a year of intense focus on the details today to optimize the battery technology of tomorrow. We’re developing new form factors for tailored battery systems to serve different vehicles, integrating additional and lower-cost cell chemistries that can deliver range and affordability to customers, and partnering with world-class battery cell makers to onboard these new technologies. Here’s how we’re moving the ball forward this year:

● Advancing technology: Battery innovation isn't about one breakthrough - it's about advancing performance across the entire value chain. That’s why continued R&D on next-generation cell chemistries and form factors, along with steady progress at our battery development and production facilities, will be a major focus. These advancements are aimed at reducing costs, improving energy density, increasing charging speed, and driving sustainability.

● Reducing battery costs: Significant reductions in EV battery costs are within reach, driven by innovations in production processes and material science. In fact, we expect to reduce our combined battery cell and pack costs by $30 per kilowatt hour in 2025. As an industry, battery prices declined in 2024 globally and are expected to continue to come down as many manufacturing investments launch in volume across North America. At GM, we are at the forefront of these advancements, helping to ensure that EVs become more attainable for a broader audience while maintaining high standards of performance and reliability.

● Strengthening North American leadership: GM’s strategic investments and partnerships are expected to bolster the domestic supply chain, create jobs, and enhance North America’s competitiveness in the global EV market. We will continue development of our next-generation battery platform, while moving with urgency to progress key construction activities and ensuring our battery materials supply base does the same. GM is leading the way in American EV infrastructure investments and we continue to secure agreements to localize our supply chain down to the raw materials

Stick with us on this journey! I hope to look back at 2025 as a year that GM drove more innovation and cost-savings in our batteries - boosting EV adoption and making electric vehicles a more compelling option for drivers everywhere.

1Requires available Max Range battery. On full charge based on development testing and/or analytical projection consistent with SAE J1634 revision 2017 - MCT. Range subject to change prior to production. Actual range may vary based on several factors, including ambient temperature, terrain, battery age and condition, loading, and how you use and maintain your vehicle.