By Jenn McKeogh, senior manager, GM News

Workers at Tonawanda Engine, formerly the Chevrolet Motor and Axle Plant, assembly six-cylinder motors, circa 1938.

Nestled along the Niagara River in Buffalo, New York, the Tonawanda Propulsion plant has been producing engines for General Motors’ vehicles since 1938.

“This plant is 87 years old and an icon in the western New York region,” says Tara Wasik, regional plant director for both Tonawanda and St. Catharine's Propulsion, which is less than 35 miles away in Ontario. “Having spent 26 years of my career here, I feel a deep sense of pride."

The 3.1 million square foot, 190-acre Tonawanda campus was originally built to assemble six-cylinder engines and axles for Chevrolets – but over its rich history, this site has contributed more to the American economy than just engines. Here’s a brief timeline:

1937 - 1938: The doors open

Tonawanda plant construction (circa 1937).

GM broke ground for the new facility in 1937, opening a year later as the “Chevrolet Motor and Axle Plant." The facility initially focused on production of inline six-cylinder engines and axle assemblies.

1941 - 1945: Supporting the war effort

Tonawanda’s first plant manager Alfred Gulliver (far right) with Chevrolet manufacturing director Hugh Dean (far left), Lt. Col Donald O'Neil (left), and an unknown man (right) as they inspect the 60,000th Pratt & Whitney radial nine-cylinder aircraft engine built in Tonawanda (circa 1945).

GM played a major role in supporting the American military during World War II. Starting in early 1942 through the end of the war, the company ceased production of civilian vehicles and converted U.S. operations to produce military supplies – like artillery shells, tanks, and engines.

Western New York served as a hub for military production, including Tonawanda. As the plant paused manufacturing of consumer car engines, it converted its assembly lines to build 14- and 18-cylinder Pratt & Whitney aircraft engines for Allied planes like the P-61 Black Widow Night Fighter, the B-24 Liberator, and the P-47 Thunderbolt.

Around the same time, a new 750,000 sq. ft. aviation engine facility was built on the Tonawanda property, owned by the U.S. government and operated by Chevrolet. Over 64,000 aircraft engines were produced at the new site. In 1943, Tonawanda produced 10% of all U.S.-built aircraft engines.

1945 – 1958: Planes and automobiles

Worker at Tonawanda, formerly the Chevrolet Motor and Axle Plant, assembling motors (circa 1951).

When the war ended, GM returned to producing consumer vehicles and components. Tonawanda returned to its former role assembling six-cylinder engines, including the engine for the iconic Chevrolet Corvette upon its debut in 1953.

The 1950s also saw reactivation of Tonawanda’s Aviation Engine Plant, which produced components for Curtiss-Wright aircraft engines. Meanwhile, Tonawanda continued to build engines for consumer vehicles, including the first aluminum piston engines, a 162-horsepower V-8, and a 170-hp engine with GM’s two-speed Powerglide automatic transmission

In 1958, one of the plant’s most notable products was introduced: the Mark series Chevrolet “big block,” starting with the 348 cubic inch (5.7L) Mark I, which was used in the Chevy Impala and Bel Air.

1959 – 1969: Blocks big and small

Manufacturing employee at Tonawanda (circa 1960s).

In 1959, Tonawanda began producing engines for the Chevrolet Corvair, the brand's first air-cooled, rear-engine vehicle. The former Aviation Engine Plant, with its 535,000 square feet of useable space, was purchased by GM from the U.S. government and used to build vehicle engines.

During the 1960s, six lines were used to assemble 16 engine models at the plant, including small and big block V-8s, the straight six, straight four, and flat six – Tonawanda built a combined 9,199,000 engines built at Tonawanda throughout the decade.

1970 – 1989: Ever expanding

A Tonawanda employee stacking components (circa 1988).

Production continued to expand at Tonawanda throughout the 1970s. A new assembly building was acquired in 1971 and designated as “Plant no. 5,” adding to the site’s manufacturing footprint. In 1975, GM added a limited-production 4-cylinder to the plant’s lineup, with each engine hand-assembled by one operator - a first for the American auto industry. Shortly after, Chevrolet's first V-6 was introduced, another Tonawanda exclusive.

The 1980s brought a variety of new products at the plant, from 2.8L and 4.3L V-6 engines to the Mark V. In June 1988, the plant hit a world record for engine production, building 8,832 engines in one day.

1990 – 1999: New name, new investments

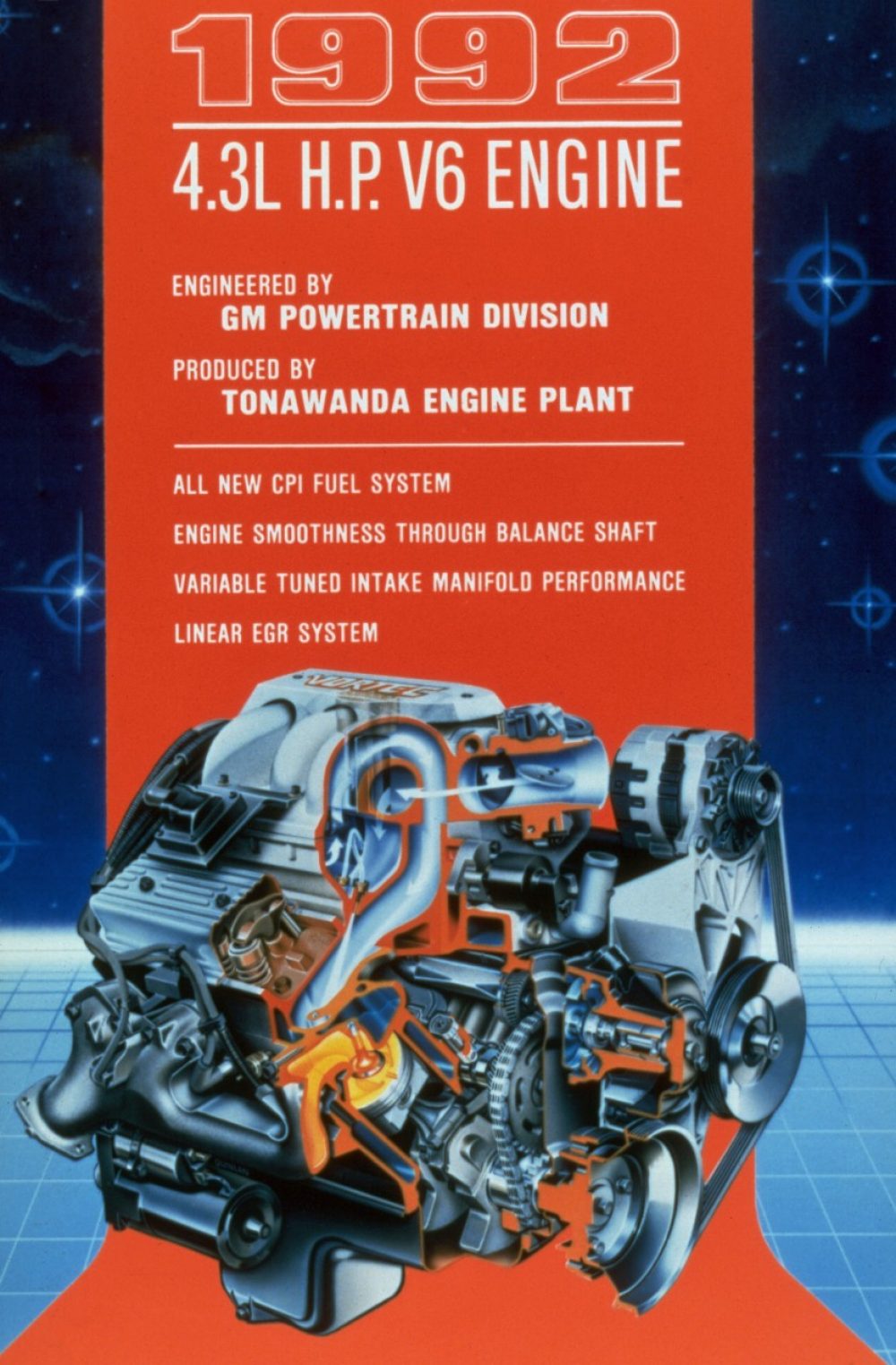

An ad from 1992 featuring the 1992 V-6 engine produced at Tonawanda Engine.

In 1990, Tonawanda was officially renamed General Motors Powertrain. A slew of milestones, investments, and new products soon followed.

1991: GM invested $37 million to produce next-gen V-6 engines.

1992: Tonawanda ranked the most productive engine facility in GM by Harbour & Associates.

1993: Tonawanda announces a $121 million investment, creating 585 new jobs.

1995: Employees build 1,922,900 engines in one year, a record

1997: GM announces Tonawanda will produce the new L850 World Engine for Saturn.

2000 – 2020:

General Motors Powertrain plant exterior (circa 2000s).

The turn of the century kicked off with a bang: In 2000, GM announced a $500 million dollar investment to expand Tonawanda’s footprint and produce new inline 4/5-cylinder engines, with plans to launch the new products in 2003.

New launches and investments continued through the 2000s, including new 3.5 and 3.9L V-6 engines in 2003, 2.0 and 2.5L 4-cylinder engines in 2012, and the Gen V small block in 2014. A total of $2.9 billion was invested in the site across a decade – a testament to the quality of Tonawanda’s products and the dedication of its workforce.

2020 – present

In 2024, the plant was renamed Tonawanda Propulsion Systems and given new signage.

In 2024, GM gave the plant a new name: Tonawanda Propulsion Systems. The site currently builds a variety of engines for vehicles across Cadillac, Chevrolet, GMC, and Buick – including the 6.2L LT2 Small Block V8, which powers the Corvette Stingray and E-Ray. This summer, Tonawanda will mark its 77th million engine build.

But the plant's most impactful contribution isn’t made of metal. It’s about the people.

“My family has been part of Tonawanda for as long as the plant has existed - from my great-grandfather who built aircraft engines to support the Allied war effort in the 1940s, to my grandfather and dad who built Chevy Big Block Engines that powered the famous muscle cars of the 60’s and 70’s,” says John Kehoe, a senior manufacturing engineer and fourth-generation Tonawanda employee. “And now I work as the Lead Engineer for the line building the engine that goes into today’s Corvette Stingray. It’s such a great feeling.”

Learn more about GM’s manufacturing sites:

[TONAWANDA NEWS - LINK TBD]

GM drives America: How we’re creating jobs by investing in manufacturing

Nestled along the Niagara River in Buffalo, New York, the Tonawanda Propulsion plant has been producing engines for General Motors’ vehicles since 1938.

“This plant is 87 years old and an icon in the western New York region,” says Tara Wasik, regional plant director for both Tonawanda and St. Catharine's Propulsion, which is less than 35 miles away in Ontario. “Having spent 26 years of my career here, I feel a deep sense of pride."

The 3.1 million square foot, 190-acre Tonawanda campus was originally built to assemble six-cylinder engines and axles for Chevrolets – but over its rich history, this site has contributed more to the American economy than just engines. Here’s a brief timeline:

1937 - 1938: The doors open

GM broke ground for the new facility in 1937, opening a year later as the “Chevrolet Motor and Axle Plant." The facility initially focused on production of inline six-cylinder engines and axle assemblies.

1941 - 1945: Supporting the war effort

GM played a major role in supporting the American military during World War II. Starting in early 1942 through the end of the war, the company ceased production of civilian vehicles and converted U.S. operations to produce military supplies – like artillery shells, tanks, and engines.

Western New York served as a hub for military production, including Tonawanda. As the plant paused manufacturing of consumer car engines, it converted its assembly lines to build 14- and 18-cylinder Pratt & Whitney aircraft engines for Allied planes like the P-61 Black Widow Night Fighter, the B-24 Liberator, and the P-47 Thunderbolt.

Around the same time, a new 750,000 sq. ft. aviation engine facility was built on the Tonawanda property, owned by the U.S. government and operated by Chevrolet. Over 64,000 aircraft engines were produced at the new site. In 1943, Tonawanda produced 10% of all U.S.-built aircraft engines.

1945 – 1958: Planes and automobiles

In 1959, Tonawanda began producing engines for the Chevrolet Corvair, the brand's first air-cooled, rear-engine vehicle. The former Aviation Engine Plant, with its 535,000 square feet of useable space, was purchased by GM from the U.S. government and used to build vehicle engines.

During the 1960s, Tonawanda built a combined 9,199,000 engines across six lines, with 16 engine models that included small and big block V-8s, the straight six, straight four, and flat six.

1970 – 1989: Ever expanding

Production continued to expand at Tonawanda throughout the 1970s. A new assembly building was acquired in 1971 and designated as “Plant no. 5,” adding to the site’s manufacturing footprint. In 1975, GM added a limited-production 4-cylinder to the plant’s lineup, with each engine hand-assembled by one operator - a first for the American auto industry. Shortly after, Chevrolet's first V-6 was introduced, another Tonawanda exclusive.

The 1980s brought a variety of new products at the plant, from 2.8L and 4.3L V-6 engines to the Mark V. In June 1988, the plant hit a world record for engine production, building 8,832 engines in one day.

1990 – 1999: New name, new investments

In 1990, Tonawanda was officially renamed General Motors Powertrain. A slew of milestones, investments, and new products soon followed.

- 1991: GM invested $37 million to produce next-gen V-6 engines.

- 1992: Tonawanda ranked the most productive engine facility in GM by Harbour & Associates.

- 1993: Tonawanda announces a $121 million investment, creating 585 new jobs.

- 1995: Employees build 1,922,900 engines in one year, a record

- 1997: GM announces Tonawanda will produce the new L850 World Engine for Saturn.

The turn of the century kicked off with a bang: In 2000, GM announced a $500 million dollar investment to expand Tonawanda’s footprint and produce new inline 4/5-cylinder engines, with plans to launch the new products in 2003.

New launches and investments continued through the 2000s, including new 3.5 and 3.9L V-6 engines in 2003, 2.0 and 2.5L 4-cylinder engines in 2012, and the Gen V small block in 2014. A total of $2.9 billion was invested in the site across a decade – a testament to the quality of Tonawanda’s products and the dedication of its workforce.

2020 – present

In 2024, GM gave the plant a new name: Tonawanda Propulsion Systems. The site currently builds a variety of engines for vehicles across Cadillac, Chevrolet, GMC, and Buick – including the 6.2L LT2 Small Block V8, which powers the Corvette Stingray and E-Ray. This summer, Tonawanda will mark its 77th million engine build.

But the plant's most impactful contribution isn’t made of metal. It’s about the people.

“My family has been part of Tonawanda for as long as the plant has existed - from my great-grandfather who built aircraft engines to support the Allied war effort in the 1940s, to my grandfather and dad who built Chevy Big Block Engines that powered the famous muscle cars of the 60’s and 70’s,” says John Kehoe, a senior manufacturing engineer and fourth-generation Tonawanda employee. “And now I work as the Lead Engineer for the line building the engine that goes into today’s Corvette Stingray. It’s such a great feeling.”

Learn more about GM’s manufacturing sites:

- GM to invest $888 million in Tonawanda Propulsion plant

- GM drives America: How we’re creating jobs by investing in manufacturing