By Mandira Ganti, intern, Tech Communications

By Mandira Ganti, intern, Tech Communications

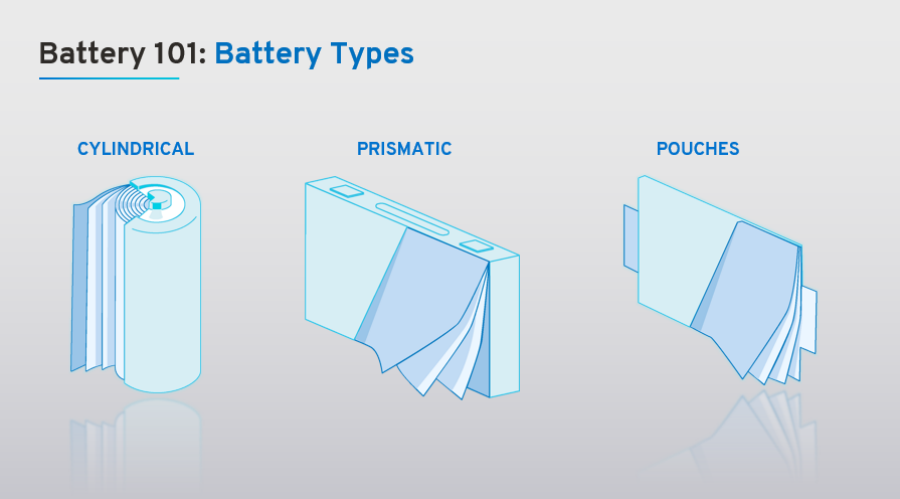

Electric vehicle batteries come in many variations – and that includes their shape and size. Automakers have multiple considerations when choosing a battery form factor, including battery chemistry, energy density, manufacturing cost, and vehicle design needs.

Think of it like packing your luggage. The items you bring determine how you pack — and the same goes for batteries. Here are the three most common form factors:

Pouch: Flexible packing cubes for clothes

Pouch cells are the most adaptable form factor, like those soft packing cubes that help you cram more clothes into your suitcase.

They don’t have a rigid casing. They’re more flexible, which allows them to pack tightly together and maximize energy density within a given space.

Without a hard casing, they require extra support from a battery module to stay in place and guard against impact, but incorporating these cells into a modular battery pack – which is how GM packages its pouch cells – can benefit battery serviceability and pack design flexibility while ensuring physical integrity and impact-resistance.

Prismatic: Rectangular hard-shell luggage

Prismatic cells are like sleek, rectangular suitcases with hard sides. They have a rigid casing, with straight edges and flat surfaces that allow them to be packed tightly with minimal wasted space.

These cells can also be larger than pouch and cylindrical cells, so each one can hold more energy. Fewer cells are needed to build a pack, and that means fewer pieces are needed to connect and hold them, bringing down overall pack costs.

Cylindrical: Hard cases for fragile items

Cylindrical cells resemble oversized AA or AAA batteries. Inside, the electrode sheets are rolled like paper towel and enclosed in a rigid metal shell.

The lack of corners helps distribute pressure evenly, making cylindrical cells durable. The curved edges prevent them from fitting perfectly flush against each other, leaving small air gaps that help regulate temperatures and provide a bit of extra cushioning.

However, because they don’t fit together neatly like a stack of books, cylindrical cells can take up more room, sometimes requiring more materials. For example, batteries that might use a few hundred pouch or prismatic cells, would need a few thousand smaller cylindrical cells to store the same amount of energy in a pack; this means increased manufacturing complexity. While these smaller cells could theoretically fit irregular pack shapes more efficiently, in practice the wiring and hardware needed to connect them can prevent full use of the space.

Why it matters:

CAPTION: From left to right, pouch, cylindrical, and prismatic battery cells photographed at a

Just like travelers choose luggage based on their priorities — protection, packing space, or simplicity — engineers select battery form factors based on their own trade-offs.

There’s no one-size-fits-all solution across the industry. For GM’s part, all current-generation EVs run on pouch cells, while future plans leverage both pouch and prismatic cells. As battery chemistries evolve and EV designs diversify, these three form factors are sure to continue to keep it all packed in place.

Electric vehicle batteries come in many variations – and that includes their shape and size. Automakers have multiple considerations when choosing a battery form factor, including battery chemistry, energy density, manufacturing cost, and vehicle design needs.

Think of it like packing your luggage. The items you bring determine how you pack — and the same goes for batteries. Here are the three most common form factors:

Pouch: Flexible packing cubes for clothes

- Pouch cells are the most adaptable form factor, like those soft packing cubes that help you cram more clothes into your suitcase.

- They don’t have a rigid casing. They’re more flexible, which allows them to pack tightly together and maximize energy density within a given space.

- Without a hard casing, they require extra support from a battery module to stay in place and guard against impact, but incorporating these cells into a modular battery pack – which is how GM packages its pouch cells – can benefit battery serviceability and pack design flexibility while ensuring physical integrity and impact-resistance.

Prismatic: Rectangular hard-shell luggage

- Prismatic cells are like sleek, rectangular suitcases with hard sides. They have a rigid casing, with straight edges and flat surfaces that allow them to be packed tightly with minimal wasted space.

- These cells can also be larger than pouch and cylindrical cells, so each one can hold more energy. Fewer cells are needed to build a pack, and that means fewer pieces are needed to connect and hold them, bringing down overall pack costs.

Cylindrical: Hard cases for fragile items

- Cylindrical cells resemble oversized AA or AAA batteries. Inside, the electrode sheets are rolled like paper towel and enclosed in a rigid metal shell.

- The lack of corners helps distribute pressure evenly, making cylindrical cells durable. The curved edges prevent them from fitting perfectly flush against each other, leaving small air gaps that help regulate temperatures and provide a bit of extra cushioning.

- However, because they don’t fit together neatly like a stack of books, cylindrical cells can take up more room, sometimes requiring more materials. For example, batteries that might use a few hundred pouch or prismatic cells, would need a few thousand smaller cylindrical cells to store the same amount of energy in a pack; this means increased manufacturing complexity. While these smaller cells could theoretically fit irregular pack shapes more efficiently, in practice the wiring and hardware needed to connect them can prevent full use of the space.

Why it matters:

Just like travelers choose luggage based on their priorities — protection, packing space, or simplicity — engineers select battery form factors based on their own trade-offs.

There’s no one-size-fits-all solution across the industry. For GM’s part, all current-generation EVs run on pouch cells, while future plans leverage both pouch and prismatic cells. As battery chemistries evolve and EV designs diversify, these three form factors are sure to continue to keep it all packed in place.